The manufacturer of forestry machinery explains why stumps shouldn’t be just dug out

To use the Dipperfox 850PRO, vertical stump grinder, carrier excavators need to be big enough to dig out basically any size of stumps. So why grinder to remove stumps?

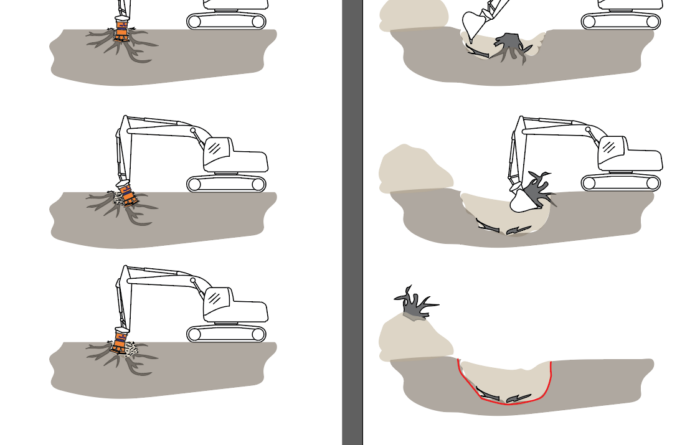

The reasoning behind investment in Dipperfox is a smaller ecological footprint. To dig the stump out, the operator needs to crush the roots from both sides of the stump. Once done, the stump can be removed.

So at least 4-5 buckets of material will be removed together with the stump. And the area affected by the digging is at least 15 times as big as the stump’s diameter.

With the Dipperfox Vertical Stump Grinder, the only area of impact is where the stump is actually located. Even if you go under the ground to smash the roots, the footprint on the surface will be significantly smaller than the digging.

Less damage means better access with equipment

Besides the ecological aspect, there are other pragmatic reasons to minimize the open areas in construction sites.

The most important factor is accessibility with construction machines. If the stumps are dug out, the craters will need to be filled to ensure access for machines, using wheels instead of tracks. And when the crates are filled, the protective layer of turf roots is damaged.

In wet conditions, it usually means a lot of mud and stuck machines.

With the Dipperfox Vertical Stump Grinder, only the wooden part of the stump will be grinded. The rest of the landscape will maintain the carrying capacity it initially has.

Efficiency and cost

The efficiency of the Dipperfox Stump Grinders stands on two main objectives:

working speed and,

debris removal.

Even the most experienced operators need extra time for making 5 moves with the excavator bucket than just aim and drill. And even in the case of bigger stumps, where drilling of multiple craters is required, it still will be much faster than digging it out.

The second and even more significant game-changer are processes that take place after the stump has been removed. With Dipperfox, the material left behind is wooden chips, turning to fertiliser in the soil over the winter months.

The stumps, which have been dug out, need to be collected, piled, dried, separated from the soil from wooden material and transported into the chipper. The remaining holes left behind need to be filled with soil.

Fewer side effects

Digging out the stumps is usually quite intensive work for the equipment, and it requires a high RPM from the excavator. This impacts both fuel consumption and noise emission.

Dipperfox, on the other hand, doesn’t need high engine reps and the work itself is much quieter, which is beneficial for both the operator and environment. Running an excavator with a lower engine speed reduces its wear and tear. It saves boom joints, cylinder loops and other moving parts, which will make the most of the stress of intense work.

Digging stumps out

Pros:

-smaller initial investment

-only option, if needed to get all the roots from the ground

Cons:

-bigger ecological footprint

-more time consuming compared to Dipperfox

-requires lot of efforts after stumps are removed (waste treatment, filling the craters)

-much more challenging for equipment

-higher fuel consumption compared to Dipperfox

Grinding stumps with Dipperfox vertical Stump Grinder

Pros:

-super effective with stumps (average stump takes about 20 seconds)

-minimum risk of throwing material around (max speed is only 60 RPM)

-can be used below the ground level (operators can use blades over rocks)

-no waste left behind (chipped material can be used as fertiliser to the ground)

Cons:

-does not churn the smaller roots

-bigger initial investment