Insulation systems: Less testing and more knowledge enable innovation and sustainability

Researchers at the Fraunhofer WKI and the Technical University of Braunschweig have developed models for predicting the overall behavior of external thermal insulation composite systems (ETICS) in timber construction. In the future it will be easier to integrate new components into already approved ETICS. In addition, ways are opening up for material innovations, especially with renewable raw materials. ETICS that have already been approved can be optimized thanks to the new findings on usability.

ETICS, which are used for the thermal insulation of exterior walls on buildings, are already widely used in construction. An ETICS consists of several coordinated components. The testing and approval of the entire system is time-consuming. Proof of use under building law is required for use. If an ETICS is approved, the components must not be exchanged without further ado, otherwise the approval will lose its validity.

ETICS are complex systems in which the interaction of the system components has not yet been adequately researched. We took a holistic view of the interaction of all system components in combination with eco-insulating materials and the wood construction as the subsurface. The basic data that we have collected enable individual components of ETICS to be exchanged and approval to be simplified. In addition, our calculations make the components safer and more reliable”

Norbert Rüther, project manager at the Fraunhofer WKI

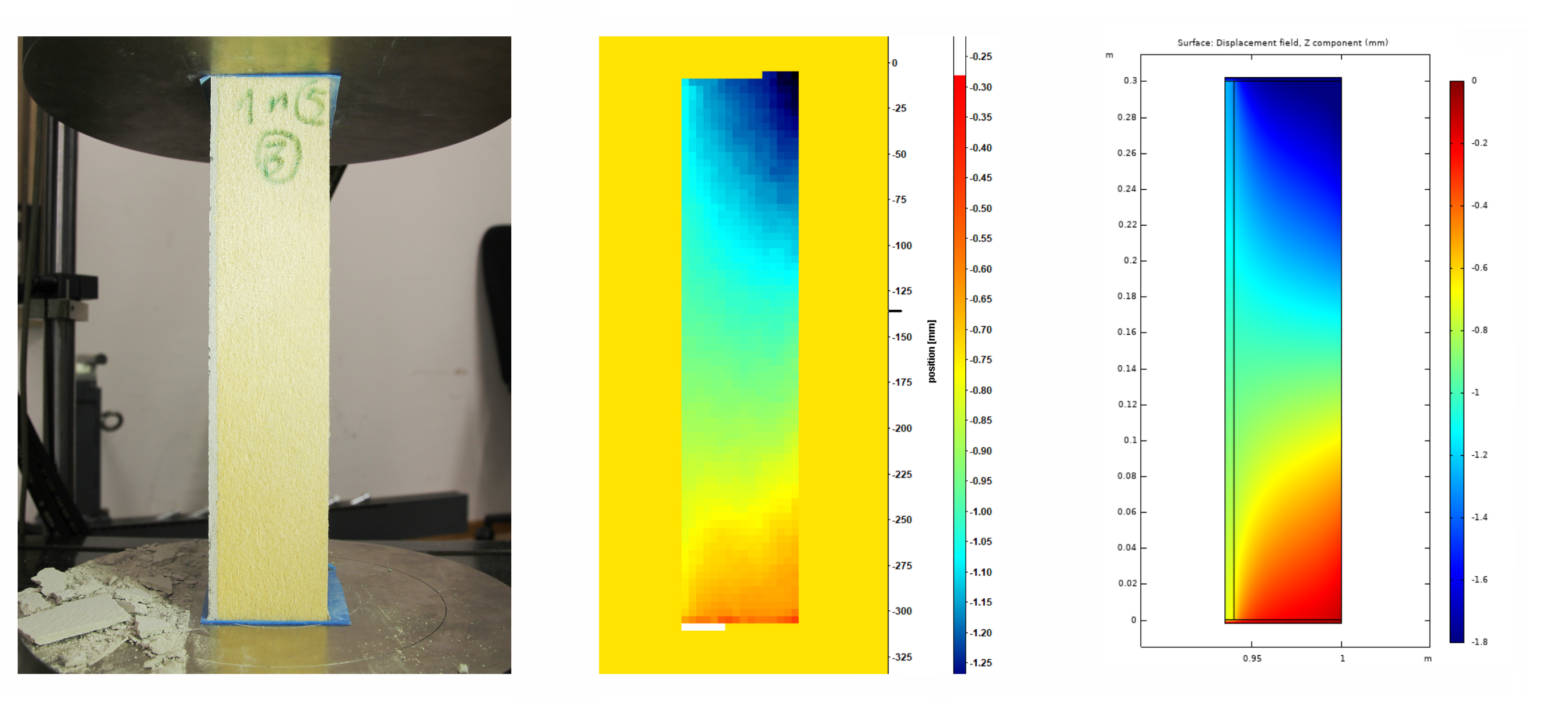

Together with the project partner, the iBHolz Institute for Building Construction and Timber Construction at the Technical University of Braunschweig, the researchers examined the individual system components: finishing plaster, concealed plaster, fabric, insulation board, fasteners and subsurface. Systems with wood fiber insulation materials on wooden substrates such as wood panel construction and solid wooden substrates were examined. At the TU Braunschweig, the researchers carried out theoretical and numerical studies on single and multi-component systems and created the models. At the Fraunhofer WKI, the scientists carried out tests on materials and two-component systems, as well as numerical studies on heat and moisture transport.

In our work, we assumed that the entire ETICS can be reduced to physical properties and processes. There are numerous types of plaster, for example, but we can describe them with sufficient accuracy with physical properties such as modulus of elasticity and strength, yield point and elongation at break, water absorption and conduction, thermal conductivity and heat storage capacity and thickness. This also applies to the insulation material or the wooden substrate.

Rüther

The researchers proceeded in three steps. First, the individual technical properties of each component were determined and then a selection of the relevant technical properties was made. The researchers then determined the influences of the components on the overall system and created a model for predicting system behavior and deriving the system boundaries. The results ultimately lead to the creation of a guideline, which is currently still being developed.

With the results of the research project, innovations would also be possible for small companies that, for reasons of cost, have not been able to carry out costly studies up to now. Overall, the time and cost expenditure for companies would be significantly reduced and innovations could find their way onto the market more quickly. For example, a newly developed plaster could be established without checking the overall system. From the results, however, better prognoses for the usability of wooden structures can be derived. This clears the way for the increased material use of renewable raw materials and their safe and permanent use. The increased use of wood-based materials in construction leads to longer-term storage of CO2 and makes an important contribution to resource efficiency and the bioeconomy.

About the background of the Fraunhofer WKI

Sustainability through the use of renewable raw materials has been the focus of the Fraunhofer WKI for 75 years. The institute with locations in Braunschweig, Hanover and Wolfsburg specializes in process engineering, natural fiber composite plastics, binders and coatings, wood and emission protection, quality assurance of wood products, material and product tests, recycling processes and the use of organic building materials and wood in construction. Almost all processes and materials that result from research are used industrially.