MAHLE supports Liebherr in developing hydrogen-fueled heavy-duty engines

MAHLE Powertrain, the development service provider of automotive supplier MAHLE is supporting Liebherr Machines Bulle SA in their research aimed at developing hydrogen-fueled internal combustion engines. Their work involves the use of MAHLE’s prechamber jet ignition system (MJI). Engine tests have shown that by using this technology, the mixture of hydrogen and air can be ignited and burned at a high compression ratio, which makes the combustion process very efficient and stable.

This paves the way for hydrogen generated in climate-neutral processes to be used in heavy-duty and off-road applications, such as excavators, track vehicles, and wheeled loaders.

“The use of hydrogen as a combustion fuel has the potential to make many heavy-duty and off-road applications climate-neutral quickly. A large number of studies in recent decades have shown that hydrogen can be used in internal combustion engines without any problems.”

Peter Wieske, Director Corporate Advanced Engineering at MAHLE.

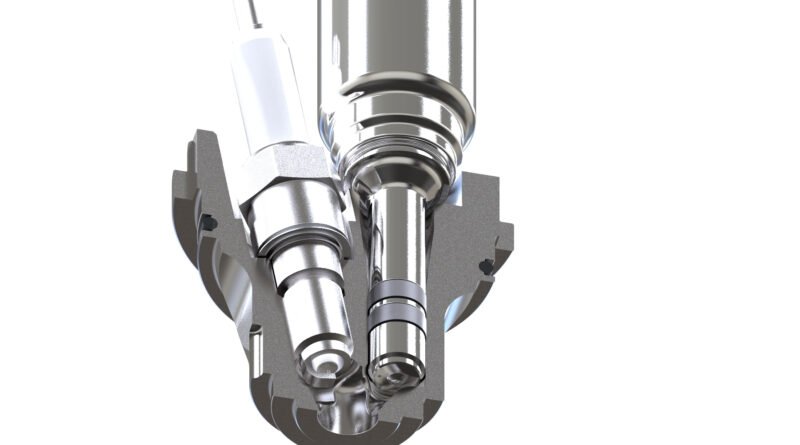

In order to achieve stable operation with a high compression ratio whilst avoiding engine knock and pre-ignition, hydrogen engines must be operated with a large amount of excess air. The energy from a conventional spark plug is not enough to ignite such a mixture. MAHLE Jet Ignition solves the problem by burning a small amount of an ignitable mixture in a prechamber cylinder. The resulting gas plasma is passed through small openings into the main combustion chamber and, due to its high energy content, rapidly and evenly ignites the main gas mixture. Tests with H966 and H964 engines from Liebherr have delivered excellent results in terms of combustion speed, performance, and emissions.

“The expertise of Liebherr’s engineering teams in off-highway engine combustion and research on alternative fuels has been critical in this project”.

Bouzid Seba, Head of Predevelopment at Liebherr Machines Bulle.

He underscores Liebherr’s open approach to all technologies, whereby the company explores various methods of energy conversion and the fuels that are most suited to them.

“The challenge is to stop engine knocking and premature ignition without reducing the compression ratio and thus efficiency and performance yield. Our joint tests suggest that we have found the right solution with MAHLE Jet Ignition”

Mike Bunce, Head of Research for MAHLE Powertrain US.

Hydrogen engines are ideal for high load cycles with sudden load changes and cope well with heat, dust, and vibrations. This makes them an excellent choice for use in heavy-duty and off-road applications, where fuel cells hit their limits more quickly.

MAHLE traditionally has strong expertise in air management, filtration, thermal management, and power electronics. The Stuttgart-based technology group already has around 100 employees working on hydrogen-related projects. MAHLE has been a supplier for fuel cell vehicles for more than ten years and operates a hydrogen test center on a 1,400-square-meter site in Stuttgart. As a member of the Hydrogen Council, it also campaigns at a political level for the expansion of hydrogen technology.